About Us: Crafting Excellence in Plastics Since 1995

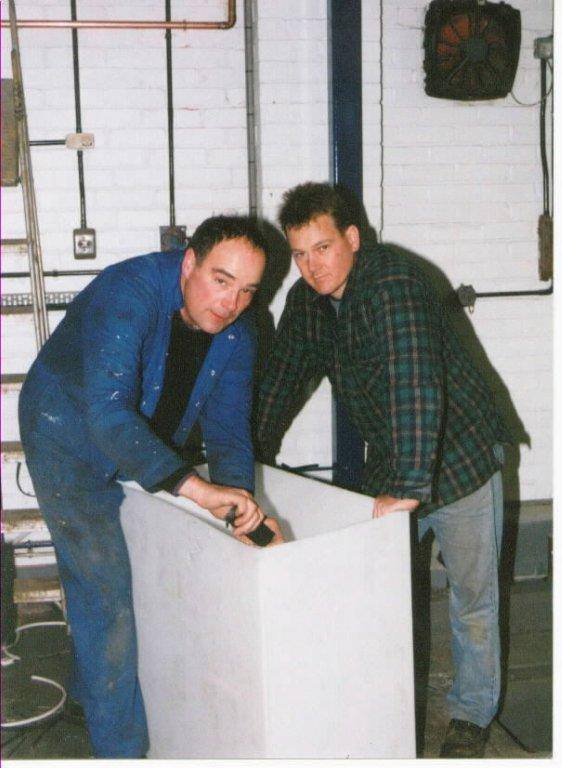

Welcome to Formation Plastics, where our journey began in 1995 in a small workshop in Rodley with two men and a vision – a vision to provide the highest level of service for all your plastic needs. Our commitment to exceptional service and quality craftsmanship has been the driving force behind our growth and success.

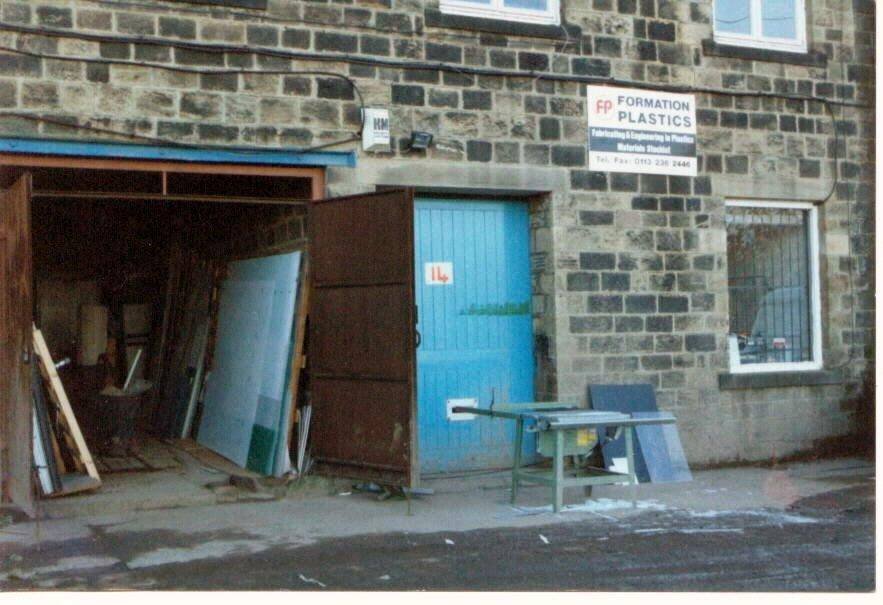

Where It Started

In 1995, our small workshop laid the foundation for what would become a hub of expertise in plastic fabrication and engineering. With a focus on experience and product knowledge, we embarked on a journey to offer unparalleled solutions in the world of plastics.

Present Day

Fast forward to today, and Formation Plastics has evolved into a thriving enterprise with 15 dedicated staff operating in a spacious 15,000 square foot workshop. Our growth has been marked by a continuous expansion of machinery, incorporating cutting-edge technology to meet the evolving needs of our clients.

Why Choose Formation Plastics?

At Formation Plastics, we are not just a plastic company; we are your dedicated partner in providing high-quality plastic solutions that consistently exceed your expectations. Our commitment to excellence, coupled with cutting-edge technology and a customer-centric approach, has propelled us to become an award-winning manufacturer and fabricator for all your plastic needs. Here’s why you should choose us as your one-stop plastic company:

1. Precision Cutting Techniques

We utilize state-of-the-art technology to offer precision cuts, even for the most intricate designs. Leveraging Computer Aided Design (CAD) tools, we convert your designs into a CAD CAM format, ensuring they are ready for machining with the latest CNC technology. Your designs are securely stored, allowing for exact replicas in the future, maintaining the same level of accuracy.

2. Varied Product Portfolio

Whether you’re looking for acrylic sheet, acrylic mirror, Foam PVC, polycarbonate sheets, aluminium composite, Polypropylene sheets, or HDPE sheets, we have a comprehensive in-house portfolio. Our diverse range of products ensures that we can meet all your plastic requirements with top-notch quality.

3. Dedicated Customer Service

Your satisfaction is our top priority. Our dedicated customer service team is committed to providing you with the best experience at every step of your journey with us. From answering your inquiries to ensuring a smooth delivery process, we take pride in making sure you are happy with every aspect of your interaction with Formation Plastics.

4. Experienced Staff

Our highly qualified team brings expertise to every stage of the process, from designs and prototyping to finishing and dispatching. With years of experience, we guarantee that every order is completed to the highest standards, meeting your specifications with precision.

5. Flexible and Creative Team

We understand that every project is unique. Our flexible and creative team collaborates with you to bring your ideas to life. We work closely to tailor our solutions to your specific needs, ensuring that you receive a product that aligns perfectly with your vision.

Plastic Welding Expertise

a. Hot Gas Welding

Our hot gas welding process is an art form in itself. Using this technique, we can weld a variety of plastics, including PVC, Polypropylene, Polycarbonate, Polyethylene, and PETG. This method allows us to fabricate tanks, chutes, hoppers, tunnels, pipes, extractors, and housings with precision and expertise.

b. Extrusion Welding

Extrusion welding is a specialized technique for joining thermoplastics and composites. Our welding machines heat and melt a plastic filler material, which is then extruded onto the surface of the base material. The molten plastics cool and form a permanent bond, ensuring durability and strength in the final product.

Choose Formation Plastics for a partnership that goes beyond manufacturing – where innovation, precision, and customer satisfaction converge. Contact us today to discuss your plastic needs and experience the excellence of Formation Plastics.

Get in touch

We’d love to hear about your project and how we can help.

Please submit your enquiry below to get in touch with us directly.

Unit 8

GB Business Park,

Cutler Heights Lane,

Bradford,

BD4 9HZ

Fabrication department 01274-299-055

Acrylic department 0113-236-2446

or email us on

sales@formation-plastics.co.uk

martin@formationplastics.co.uk